When it comes to designing high-performance luggage, every component matters—from zippers and wheels to the internal lining and, most importantly, the plastic luggage handle. Often overlooked, the handle is one of the most frequently used and critical parts of any suitcase, backpack, or travel bag. Among the various materials used in handle manufacturing, plastic luggage handles have emerged as a top choice for manufacturers and travelers alike. Combining durability, lightweight design, cost-efficiency, and ergonomic comfort, plastic handles are revolutionizing the travel accessory industry.

In this in-depth article, we’ll explore what plastic luggage handles are, their key benefits, common types, materials used, and why they are the preferred option for modern luggage brands and consumers around the world.

What Is a Plastic Luggage Handle?

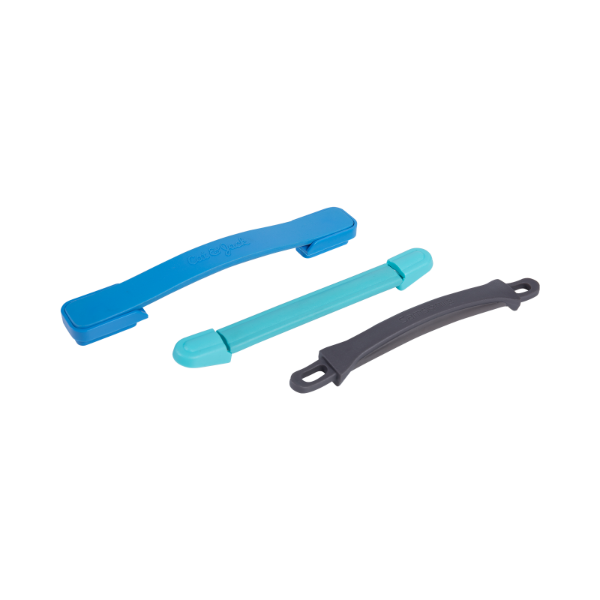

A plastic luggage handle is a molded or assembled grip component made primarily from high-strength polymers, designed to allow users to carry, lift, or pull their luggage with ease. These handles come in various forms, including:

Top handles – Used for lifting suitcases into overhead bins or onto luggage racks.

Side handles – Provide additional grip points for maneuvering heavy bags.

Telescopic handles – Extend and retract for rolling luggage, often incorporating plastic grips and internal support structures.

Integrated molded handles – Seamless handles formed directly into the luggage shell during manufacturing.

While metal and rubber handles are still used in some premium products, plastic has become the dominant material due to its versatility, resilience, and compatibility with mass production techniques.

Why Plastic? The Advantages of Plastic Luggage Handles

1. Lightweight Yet Strong

One of the biggest advantages of plastic luggage handles is their high strength-to-weight ratio. Materials like polypropylene (PP), acrylonitrile butadiene styrene (ABS), and polycarbonate (PC) offer excellent impact resistance while adding minimal weight to the overall luggage. This is crucial in an era where airlines enforce strict baggage weight limits.

Plastic handles can endure repeated stress from lifting, dropping, and dragging without cracking or deforming—making them ideal for frequent travelers.

2. Cost-Effective Manufacturing

Plastic handles are typically produced through injection molding, a process that allows for high-volume, consistent production at a low cost. This makes them an economical choice for luggage manufacturers aiming to deliver affordable yet reliable products to the market.

The ability to mold complex shapes and integrate features like soft-touch grips, anti-slip textures, and color finishes in a single production step further enhances their value.

3. Design Flexibility and Aesthetic Appeal

Plastic can be easily colored, textured, and shaped to match any luggage design. Whether you're looking for a sleek black finish, a matte grip, or a translucent accent, plastic handles can be customized to align with brand identity and consumer preferences.

Additionally, plastic allows for ergonomic shaping—curved handles that fit comfortably in the hand, reducing strain during extended use.

4. Corrosion and Weather Resistance

Unlike metal handles that can rust or corrode when exposed to moisture, salt, or humidity, plastic handles are naturally resistant to water, UV rays, and chemicals. This makes them especially suitable for travel in coastal areas, rainy climates, or environments with high humidity.

Plastic also doesn’t conduct heat or cold, so handles remain comfortable to touch in extreme temperatures—unlike metal, which can become too hot or cold to grip.

5. Shock Absorption and Durability

High-quality engineering plastics like ABS and polycarbonate blends offer excellent shock absorption. When a suitcase is dropped, the plastic handle can flex slightly and return to its original shape, preventing breakage. This resilience contributes to the overall longevity of the luggage.

Many plastic handles are also reinforced with metal inserts or internal bars to enhance load-bearing capacity without sacrificing the benefits of plastic.

6. Low Maintenance and Easy to Clean

Plastic handles are non-porous and easy to wipe clean with a damp cloth. They don’t absorb dirt, sweat, or stains like fabric or leather grips, making them more hygienic and suitable for shared or commercial use (e.g., rental luggage, airline crew bags).

Common Types of Plastic Used in Luggage Handles

| Material | Properties | Common Use |

| ABS (Acrylonitrile Butadiene Styrene) | Tough, impact-resistant, good surface finish | Top and side handles, telescopic grips |

| PP (Polypropylene) | Flexible, chemical-resistant, lightweight | Molded integrated handles |

| PC (Polycarbonate) | Extremely strong, transparent options | High-end luggage, reinforced grips |

| TPE (Thermoplastic Elastomer) | Soft-touch, anti-slip, rubber-like feel | Overmolded grips on handles |

| Nylon (PA6/PA66) | High strength, heat-resistant | Internal support structures |

Many modern handles use multi-material construction, such as a rigid ABS core with a soft TPE overmold, combining strength with comfort.

Applications of Plastic Luggage Handles

Plastic handles are used across a wide range of travel products, including:

Carry-on and checked suitcases

Duffel bags and weekenders

Backpacks and laptop bags

Wheeled tote bags

Children’s luggage

Commercial and airline crew bags

Their adaptability makes them suitable for both budget-friendly and premium luggage lines.

How Plastic Handles Improve User Experience

Beyond durability and cost, plastic luggage handles significantly enhance the user experience:

Ergonomic Design: Contoured shapes reduce hand fatigue.

Non-Slip Texture: Textured or rubberized surfaces provide a secure grip, even with wet or sweaty hands.

Silent Operation: Unlike metal handles that can rattle or squeak, plastic handles operate quietly.

Seamless Integration: Can be molded directly into the shell for a sleek, modern look.

These features make plastic handles not only functional but also a key part of the brand’s user-centric design philosophy.

Sustainability and Environmental Considerations

As the world moves toward eco-friendly manufacturing, the luggage industry is also embracing sustainable practices. Many plastic luggage handles are now made from recycled plastics or bio-based polymers. Additionally, plastic is highly recyclable at the end of its life cycle, especially when separated from mixed materials.

Leading manufacturers are investing in closed-loop recycling systems, where old luggage is collected, broken down, and repurposed into new components—including handles.

Choosing the Right Plastic Handle for Your Luggage

When selecting or designing a plastic luggage handle, consider the following factors:

Load Capacity: Ensure the handle can support the maximum weight of the luggage.

Ergonomics: Test grip comfort and handle placement.

Material Quality: Use UV-stabilized, impact-resistant plastics.

Finish and Aesthetics: Match the handle to the overall design of the bag.

Compliance: Meet international safety and durability standards (e.g., ISTA, IATA).

Working with experienced suppliers who specialize in luggage components can ensure optimal performance and reliability.

The Future of Plastic Luggage Handles

Innovation in materials science is driving the next generation of plastic handles. Emerging trends include:

Smart handles with built-in sensors (weight detection, GPS tracking)

Self-healing polymers that repair minor scratches

Antimicrobial coatings for improved hygiene

3D-printed custom handles for personalized luggage

As travel evolves, so too will the components that make it easier—and plastic luggage handles will remain at the forefront of this innovation.

Conclusion

The plastic luggage handle may seem like a small detail, but it plays a big role in the performance, comfort, and longevity of any travel bag. From its lightweight strength and weather resistance to its design flexibility and cost-efficiency, plastic offers unmatched advantages over traditional materials.

Whether you're a luggage manufacturer looking to improve product quality or a traveler seeking a reliable suitcase, don’t underestimate the importance of a well-designed plastic handle. It’s the part you touch first—and the one that ensures your journey starts smoothly.

Español

Español