A luggage grip handle is a critical component of any suitcase, travel bag, or carry-on. While it may appear to be a small and simple part, the grip handle plays a major role in user comfort, durability, and overall travel experience. A well-designed luggage grip handle reduces hand fatigue, improves control when lifting or pulling, and contributes to the perceived quality of the entire luggage product.

For luggage manufacturers, distributors, and buyers, understanding the technical and functional aspects of luggage grip handles is essential. Factors such as material selection, ergonomic design, load capacity, and attachment structure directly affect product reliability and customer satisfaction. In competitive travel goods markets, the grip handle can be a key differentiator in both premium and mass-market luggage.

Primary Functions of a Luggage Grip Handle

The main function of a luggage grip handle is to provide a secure and comfortable point of contact between the user and the luggage. This applies to top carry handles, side carry handles, and auxiliary grab handles used for lifting luggage onto conveyors, car trunks, or luggage racks.

In addition to basic lifting, a luggage grip handle must also support repeated use under varying loads and environmental conditions. It must resist cracking, deformation, and loosening over time. A poorly designed handle can lead to discomfort, hand strain, or even sudden failure, which can damage both the luggage and the user’s trust in the brand.

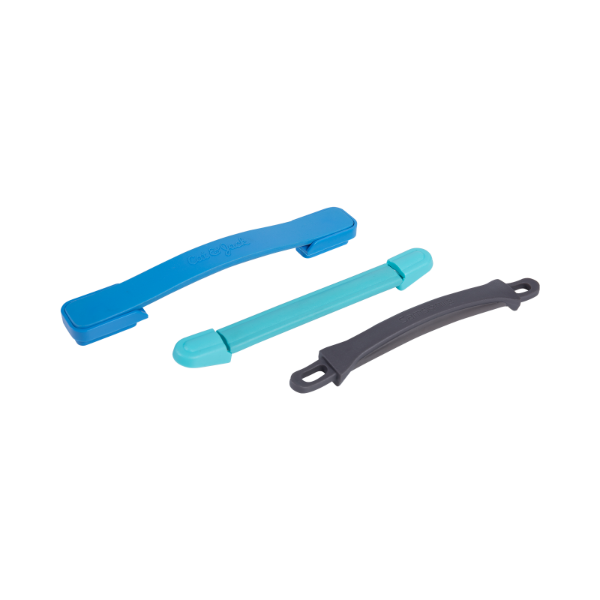

Types of Luggage Grip Handles

Luggage grip handles are available in several common types, each designed for specific positions and use cases on the bag. Selecting the right type ensures proper load distribution and user convenience.

Top Carry Handles

Top carry handles are the most frequently used luggage grip handles. They are mounted on the top panel of the suitcase and are used for lifting, short-distance carrying, and placing luggage onto elevated surfaces. These handles must balance softness for comfort with structural rigidity to support heavy loads.

Side Carry Handles

Side carry handles are positioned on the side of the luggage to make it easier to lift the suitcase in a vertical orientation. This is especially useful when placing luggage into car trunks, overhead bins, or luggage carts. Side handles must be securely reinforced because they often experience uneven loading.

Auxiliary Grab Handles

Some luggage designs include additional grab handles on the front or bottom panels. These auxiliary luggage grip handles assist with two-person lifting or pulling heavy suitcases from tight spaces. While not always used, they add convenience and reduce strain during handling.

Materials Used in Luggage Grip Handles

Material selection is one of the most important factors affecting handle durability, comfort, and appearance. Different materials offer different advantages depending on luggage positioning and target market.

- Plastic (ABS, PP, or nylon) for lightweight and cost-effective designs.

- Rubber or TPR overmolding for improved grip comfort and slip resistance.

- Aluminum or metal cores for high load capacity and premium feel.

- EVA foam or padded fabric for soft-touch and ergonomic comfort.

High-quality luggage grip handles often use a combination of materials, such as a reinforced plastic or metal core with a rubberized outer layer. This construction provides both strength and comfort, reducing pressure points on the user’s hand.

Ergonomic Design and User Comfort

Ergonomics is a key factor in luggage grip handle design. The shape, thickness, and surface texture of the handle directly influence how comfortable it feels during use. A poorly shaped handle can cause discomfort, numbness, or hand fatigue, especially when lifting heavy luggage for extended periods.

Well-designed handles typically feature contoured shapes that fit the natural curve of the hand. Rounded edges help prevent pressure concentration, while textured or rubberized surfaces improve grip security. Some premium handles include soft-touch coatings or foam padding to further enhance comfort.

Load Capacity and Structural Strength

A luggage grip handle must be engineered to support the maximum expected load with an appropriate safety margin. This includes not only the static weight of a fully packed suitcase, but also dynamic forces during lifting, dropping, or pulling.

Manufacturers often test handles for tensile strength, fatigue resistance, and impact durability. Reinforced mounting points, internal metal frames, and high-strength fasteners help ensure that the handle does not fail under real-world travel conditions. For heavy-duty or commercial luggage, higher load ratings are especially important.

Attachment Methods and Mounting Structure

How a luggage grip handle is attached to the suitcase body is just as important as the handle itself. Weak mounting can cause loosening, rattling, or complete detachment over time.

Common attachment methods include rivets, screws with metal backing plates, and molded-in mounting brackets. High-quality designs distribute load across a larger surface area to reduce stress on the luggage shell or fabric. For hard-shell luggage, internal reinforcement plates are often used to prevent cracking around the handle area.

Weather Resistance and Environmental Durability

Luggage grip handles are exposed to a wide range of environmental conditions, including heat, cold, moisture, UV light, and chemical exposure from cleaning agents or airport handling environments. Materials must be selected to resist cracking, fading, and loss of flexibility over time.

Rubber and TPR components should maintain elasticity in low temperatures, while plastic components should resist UV degradation. For metal parts, corrosion-resistant coatings or stainless steel materials help extend product life, especially in humid or coastal environments.

Aesthetic Design and Brand Positioning

Beyond function, the luggage grip handle also contributes to the overall visual identity of the suitcase. Shape, color, texture, and finish can all be customized to match brand positioning and target customer segments.

Premium luggage brands often use metal accents, soft-touch coatings, or leather-wrapped handles to communicate quality and luxury. Budget and mid-range products may focus on durable molded plastic designs that balance cost and appearance. Consistent handle design across product lines can also strengthen brand recognition.

Quality Control and Testing Standards

Reliable luggage grip handles require strict quality control during manufacturing. Common tests include load testing, cyclic fatigue testing, temperature cycling, and surface abrasion testing. These tests help identify weak points before products reach the market.

For OEM and ODM suppliers, providing documented test results and compliance with international quality standards can be an important factor for buyers. Consistent quality reduces warranty claims and improves long-term customer satisfaction.

Replacement and Aftermarket Considerations

Luggage grip handles are one of the most commonly replaced luggage components. Wear and tear, accidental damage, or airline handling can cause handle failure even when the rest of the suitcase remains usable.

Designing handles that can be easily replaced with standard tools adds value for consumers and repair services. Availability of compatible replacement handles also extends product life and supports sustainability by reducing the need to discard otherwise functional luggage.

Comparison Table: Key Luggage Grip Handle Features

| Feature | Standard Handle | Premium Handle |

| Core Material | Plastic | Metal or reinforced composite |

| Grip Surface | Hard plastic | Rubberized or padded |

| Load Capacity | Moderate | High |

| User Comfort | Basic | Enhanced ergonomic design |

Choosing the Right Luggage Grip Handle for Your Product

Selecting the right luggage grip handle requires balancing cost, durability, comfort, and brand positioning. For high-end travel products, investing in premium materials and ergonomic designs can significantly improve customer perception and reduce long-term complaints.

For mass-market luggage, standardized and proven handle designs can offer reliable performance at lower cost. Regardless of market segment, focusing on structural integrity, user comfort, and consistent quality is essential to delivering a competitive and dependable travel product.

Español

Español